We’re here to empower our country’s many innovators and entrepreneurs, helping you make real your world-bettering ideas, boost our economy and power a better standard of living for us all, now and into the future. We take our name from Sir Paul Callaghan, one of Aotearoa’s most visionary scientists and also the founder of a world-leading business.

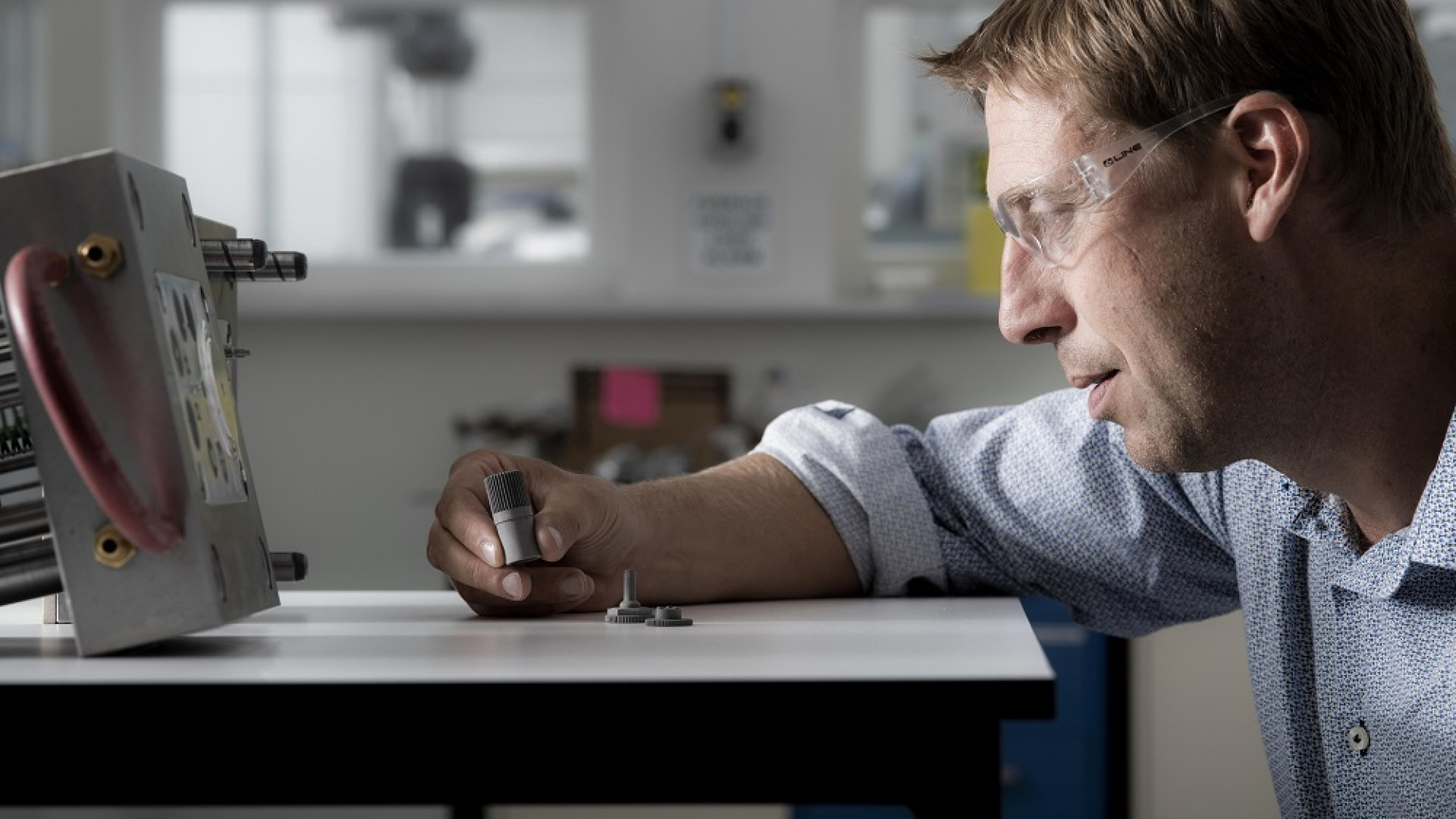

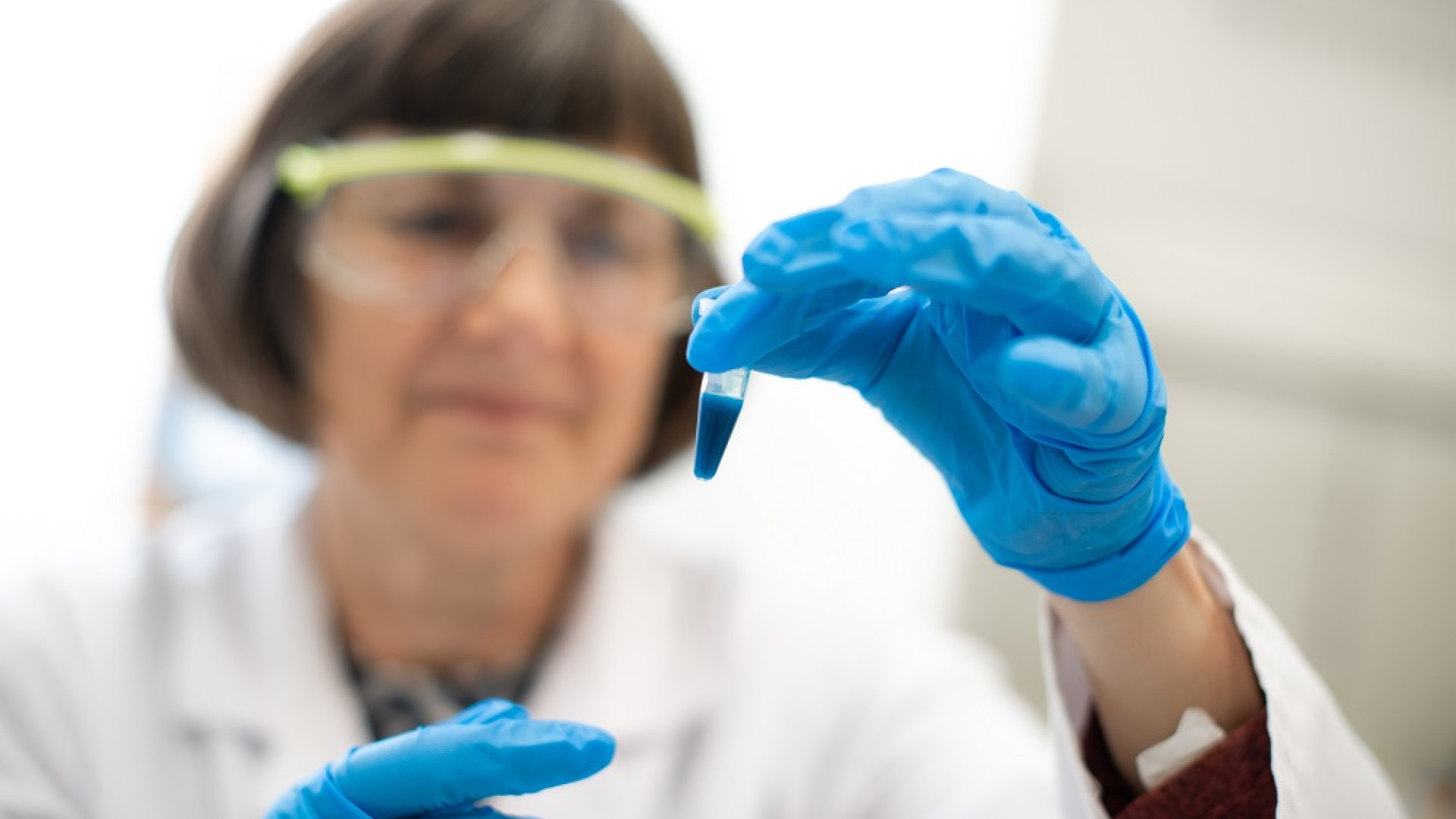

Callaghan Innovation provides funding and scientific expertise, promotes R&D, facilitates collaboration between researchers, scientists, and industry and supports the commercialisation of ideas with positive impact.

Supporting Aotearoa's innovators:

Callaghan Innovation has launched a counselling service to support founders whose mental health is suffering due to the significant pressures associated with establishing and growing a startup.

Meet the experts who support businesses like yours, and the leadership that drives the direction of Callaghan Innovation.

Explore the body of research our experts have contributed to the scientific community.

We’re proud to support or facilitate a host of diverse events for innovators and entrepreneurs across the country. Find your next unmissable one here.

Passionate about making an impact by empowering Aotearoa New Zealand’s innovators? Explore our open roles and join our mission here.

Highly knowledgeable facilitators who gave answers to our specific questions. Good framework to learn the ins and outs of IP Strategy as a novice to the topic. Good way to differentiate the different concepts like trademark, patent etc. with application examples.

"Learning about raising capital from an industry expert with a wealth of knowledge and experience makes in a way that was detailed enough yet no so specific to be exclusive was extremely valuable to us. We could have listened for hours!

"Firstly, Callaghan Innovation gave us the flexibility to commit to development activity to get us started, and secondly it allowed us to put our money into areas that would make us successful.

"The whole way through our journey we’ve been supported by either Callaghan Innovation Project or Growth Grants [now replaced by the R&D Tax Incentive], which have been absolutely critical to our operation.

"There are very few companies exploring lncRNA for oncology purposes so the process of getting the research to market is complex but the support the programme provides is crucial. It enables us to access a supportive network of like-minded people to help us as we create what has the potential to be a ground-breaking cancer therapy,

"We commenced the program when our business was undergoing a period of significant change brought about by the retirement of senior staff after the COVID locked down period. We promoted younger staff internally and the Lean program provided tremendous support and guidance whilst they found their feet with added responsibilities.

"