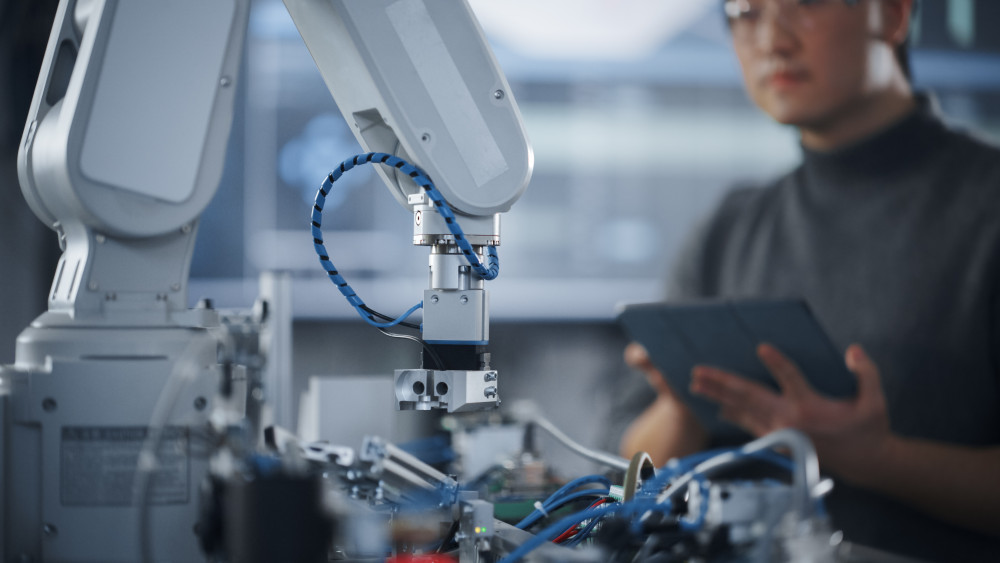

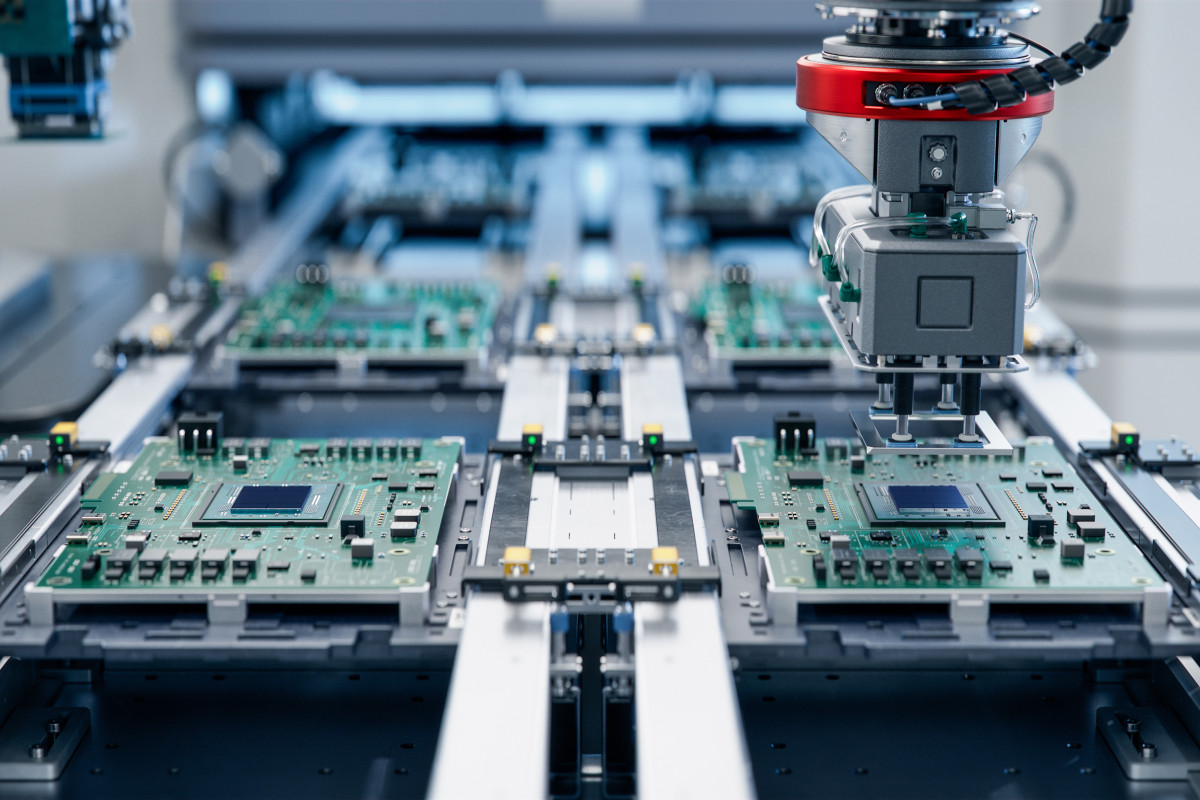

The businesses leading the Industry 4.0 revolution are on a continual journey of improvement. Their dedicated teams are forever seeking out the latest tech and improved processes to find efficiencies and cost saving measures.

Often the biggest challenge they face is benchmarking; truly understanding how well they’re doing versus others, and having the right information to inform future decisions.

The Smart Factory Assessment was set up to overcome this hurdle and help manufacturers continue to evolve and develop, and deliver even better products and services to their customers.

The assessments are based around the Smart Industry Readiness Index (SIRI), a globally recognised set of tools, frameworks and metrics, developed specifically to support manufacturers at the cutting edge of new tech.

You’ll start with an educational session, teaching and refreshing your team about key Industry 4.0 concepts, principles and terminology, as well as discussing your future aspirations.

The following day you’ll accompany your assessor around your factory as they score you against the 16 point framework, identifying your strengths and weaknesses. In the days following you’ll virtually reconvene to go through your results and suggested areas of improvement which will have the biggest positive impact.

With your roadmap in place, you and your team can set to work, creating a better product and a more sustainable and profitable business.

What is SIRI?

The Smart Industry Readiness Index (SIRI) is an internationally recognised standard for Industry 4.0 transformation. It was created by the Singapore Economic Development Board (EDB) in partnership with a network of leading technology companies, consultancy firms, and industry and academic experts.

SIRI comprises a suite of frameworks and tools to help manufacturers – regardless of size and industry – start, scale, and sustain their manufacturing transformation journeys. SIRI covers the three core elements of Industry 4.0: Process, Technology, and Organisation.

What is Industry 4.0?

Industry 4.0 - also referred to as the fourth Industrial Revolution - is a broad term for the new technologies and data - such as cloud computing, Internet of Things (IoT), and Artificial Intelligence - that are revolutionising the worlds of manufacturing and distribution. Callaghan Innovation’s experts are here to help you cut through the technology hype, reinvent your business model and find genuine value and growth.

Read MoreBenefits to your business

Assessments conducted using a suite of tools and frameworks, created by an internationally recognised body.

Learn how well you’re doing versus other organisations in your industry, and the wider manufacturing sector.

Walk away with a roadmap detailing fruitful future opportunities.

Receive a zero-cost voucher if you’re selected.

Success stories

Is this right for me?

Applications are now open for a free assessment.

To be eligible, you must have under 150 full time employees and be willing to put forward three relevant senior leaders to be involved with the assessment.

On a quarterly basis 25 businesses will be selected from the applicants. The selection matrix uses a numeric score given to each business depending on a number of factors. Upweighting is given to SMEs, businesses located outside of the established metropolitan manufacturing hubs, and those that identify as Māori businesses.

Industry 4.0 maturity and sector may also be accounted for to ensure a broad range of businesses benefit from the programme. If you’re not selected, you can opt in to remain on the list and potentially selected in the next quarter.

A total of 200 businesses will be selected before the programme closes at the end of 2025. Those selected will receive a voucher to redeem with an assessor. You must redeem your voucher within 60 days of issue.

Enquire about an assessment

Do you fall outside of the eligibility criteria, or would rather hire a SIRI assessor outside of this programme?

Please feel free to approach assessment partners directly about hiring their certified SIRI assessors.

Or, get in touch if you’d like to hire one of Callaghan Innovation’s certified SIRI assessors.

A Smart Factory Assessment would benefit any manufacturing business that has some form of connected technologies embedded into their manufacturing lines and is eager to add new technologies and Industry 4.0 principles.

What's covered?

If you’re chosen to receive a free assessment, you’ll first choose an assessor from the list below and redeem your voucher. Ahead of the visit they’ll confirm all of the details, along with any specifics required for the assessment visit.

Day One

The first day of the visit is spent with your relevant senior leaders for a workshop covering core Industry 4.0 principles, concepts and terminology, and introducing the SIRI assessment framework. This new knowledge will help your team give the most accurate information to the assessor.

During this first day the assessor will also be working to build up a broad picture of your business, your products, your customers and your goals and aspirations.

Day Two

On day two your assessor will be pulling on their PPE and setting off around the factory to undertake the 18 point assessment.

The assessment is split into three parts: process, technology and organisation. For each of the 18 points, the assessor will give a scoring between 1-5.

In addition to the standard 16 points of the SIRI assessment, our assessor will evaluate two extra points: decarbonisation and circular economy. These two metrics have been added to help benchmark sustainability efforts and outline possible future goals.

You’ll need to assign your chosen senior staff members to accompany the assessor during the day, and they may ask to discuss certain aspects of operation with relevant personnel.

Virtual Follow Up

Around two weeks later, the assessor will bring together your team again to discuss the outcomes of the assessment.

They’ll talk through the scoring, present an overall score, and show how you’re doing versus other manufacturers in relevant sectors.

The assessor will offer their suggested priorities and potential roadmap using the TIER framework: today’s state, impact to bottom line, essential business objectives and references to the broader community.

Applications are now open for a free assessment.

To be eligible, you must have under 150 full time employees and be willing to put forward three relevant senior leaders to be involved with the assessment.

On a quarterly basis 25 businesses will be selected from the applicants. The selection matrix uses a numeric score given to each business depending on a number of factors. Upweighting is given to SMEs, businesses located outside of the established metropolitan manufacturing hubs, and those that identify as Māori businesses.

Industry 4.0 maturity and sector may also be accounted for to ensure a broad range of businesses benefit from the programme. If you’re not selected, you can opt in to remain on the list and potentially selected in the next quarter.

A total of 200 businesses will be selected before the programme closes at the end of 2025. Those selected will receive a voucher to redeem with an assessor. You must redeem your voucher within 60 days of issue.

Enquire about an assessment

Do you fall outside of the eligibility criteria, or would rather hire a SIRI assessor outside of this programme?

Please feel free to approach assessment partners directly about hiring their certified SIRI assessors.

Or, get in touch if you’d like to hire one of Callaghan Innovation’s certified SIRI assessors.

A Smart Factory Assessment would benefit any manufacturing business that has some form of connected technologies embedded into their manufacturing lines and is eager to add new technologies and Industry 4.0 principles.

What's covered?

If you’re chosen to receive a free assessment, you’ll first choose an assessor from the list below and redeem your voucher. Ahead of the visit they’ll confirm all of the details, along with any specifics required for the assessment visit.

Day One

The first day of the visit is spent with your relevant senior leaders for a workshop covering core Industry 4.0 principles, concepts and terminology, and introducing the SIRI assessment framework. This new knowledge will help your team give the most accurate information to the assessor.

During this first day the assessor will also be working to build up a broad picture of your business, your products, your customers and your goals and aspirations.

Day Two

On day two your assessor will be pulling on their PPE and setting off around the factory to undertake the 18 point assessment.

The assessment is split into three parts: process, technology and organisation. For each of the 18 points, the assessor will give a scoring between 1-5.

In addition to the standard 16 points of the SIRI assessment, our assessor will evaluate two extra points: decarbonisation and circular economy. These two metrics have been added to help benchmark sustainability efforts and outline possible future goals.

You’ll need to assign your chosen senior staff members to accompany the assessor during the day, and they may ask to discuss certain aspects of operation with relevant personnel.

Virtual Follow Up

Around two weeks later, the assessor will bring together your team again to discuss the outcomes of the assessment.

They’ll talk through the scoring, present an overall score, and show how you’re doing versus other manufacturers in relevant sectors.

The assessor will offer their suggested priorities and potential roadmap using the TIER framework: today’s state, impact to bottom line, essential business objectives and references to the broader community.

Resources

Ready to transform your business?

Get started today!

Begin your assessment.