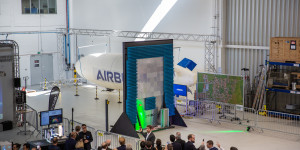

It may be the only factory of its kind in the Southern Hemisphere, but Pyrotek, supported by Callaghan Innovation, is punching above its weight when it comes to ceramics manufacturing.

At a glance

- Pyrotek, with the only factory of its kind in the Southern Hemisphere, is a manufacturer of mid-to high-end ceramic consumables for the aluminium foundry and smelting industries.

- The manufacturer has developed a longstanding relationship with scientists at Callaghan Innovation to assist with its ongoing R&D.

- The partnership has resulted in product innovation that has helped move the manufacturer’s products up the value chain, and also keep the operation viable in a tough manufacturing climate.

We’re in the ceramics game, but we’re in a very specific part of the ceramics game. Having access to that [Callaghan Innovation’s] perspective, through a strong advisor with which we have a long relationship, is hugely beneficial to us.

Sean Dillon - New Zealand Manager, Pyrotek

A manufacturing island on their own

Pyrotek is a large, US-based firm offering engineering and technology solutions. Yes, it has more than 80 locations in 35 countries, and yes it has customers in a broad range of industries.

But Pyrotek’s New Zealand operations are among their smallest globally, explains Pyrotek’s New Zealand manager, Sean Dillon. Its Auckland manufacturing facility is a specialist producer of mid- to high-end ceramic consumables for aluminium foundries and smelters.

“There are no other factories like ours in the Southern Hemisphere,” says Dillon, “so we’re very much on an island of our own, both physically, and in terms of what we manufacture.”

So who do you turn to for information, advice and support when developing new products, troubleshooting problems, or gaining insights into future opportunities?

For Pyrotek, the answer is Callaghan Innovation.

In it for the long haul

A partnership spanning almost three decades, Pyrotek has worked with the Research and Development Solutions team at Callaghan Innovation in a bid to continue to innovate despite a tough manufacturing climate, and in the face of strong global competition.

“It’s always been a collaborative relationship,” says Dr Pauline Calloch, an Advanced Materials research scientist in Callaghan Innovation’s Metals and Ceramics team, of her work with Pyrotek.

“They bring their expertise in their industry, and their deep knowledge of their customers’ industry and large-scale production, while we bring a deep, fundamental understanding of ceramics - the material they are producing.”

As well as producing a new ceramics material, Pyrotek and Callaghan Innovation have continued to work together to innovate on a more iterative level. Callaghan Innovation’s ability to reproduce Pyrotek’s manufacturing processes on a small scale has helped significantly, says Calloch. Dillion says this gives Pyrotek a means to test new ideas in a cost-effective way that doesn’t interrupt production, which significantly diminishes risk.

Dillon also says being able to draw upon the scientists’ wider materials knowledge has been a major asset on a number of fronts.

“Ceramics is what they call ‘the black art’; there is a lot of science behind these materials so there’s a lot more variability when working with them than with, say, metal products. For example, around 18 months ago we had a significant cost issue related to a manufacturing defect problem. We took advice from Callaghan Innovation around a particular step in our manufacturing, which significantly improved the consistency of our product.”

Another task Calloch undertook for the company was a literature review, investigating relevant new developments in the field of ceramics. Gaining that perspective is not only important to inform future product development, says Dillon, but also to ensure any capital investment in plant, which can extend into the millions of dollars, is also future proofed.

“We’re in the ceramics game, but we’re in a very specific part of the ceramics game. Pauline, through her work with Callaghan Innovation and different customers, is exposed to a much wider range of materials and techniques - some of which ultimately could be translatable to what we do. Having access to that perspective, through a strong advisor with which we have a long relationship, is hugely beneficial to us,” says Dillon.

Transforming products and the business

With such a strong, long-term partnership, Pyrotek has been able to put innovation at the heart of the business and ultimately ensure longevity.

The ceramic material mentioned, that Pyrotek and Callaghan Innovation developed together, was called O-Sialon (standing for a mixture of silicon, aluminium, oxygen and nitrogen), and is being used to make products harder, stronger and tougher than traditional ceramics.

This innovation proved transformative for the business. With more durable ceramics, it meant Pyrotek could expand into the higher-value end of its market as well as explore export opportunities.

That market repositioning, says Dillon, helped the manufacturing operation endure, even as the market for that technology matured, and global producers of ultra high-end ceramics, such as Kyocera, enjoyed a large market share.