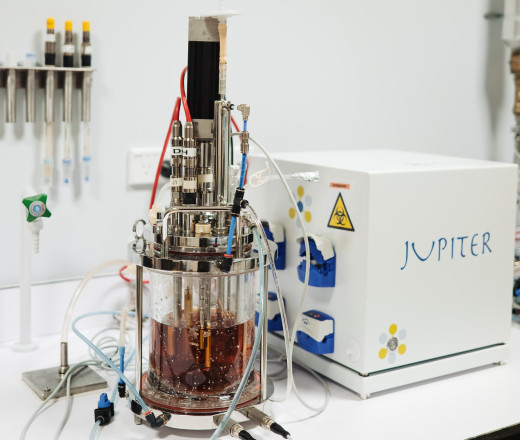

Fermentation technology is rapidly expanding globally to create novel and sustainable sources of food, nutraceuticals, natural alternatives to synthetic products and pharmaceuticals.

Our deep expertise in bench to pilot scale submerged liquid fermentation, including precision fermentation, offers scalable solutions to innovators developing alternative proteins, novel probiotics and crop, animal and human health products.

We are the only end-to-end facility in New Zealand with the upstream development, pilot scale fermentation capability and downstream processing for accelerating bioprocessing.

When this is helpful

Fermentation for whole cell products

Maximise microbial biomass as a natural ingredient.

We have extensive experience in scaling up biomass fermentation as a submerged fermentation process, using a range of microoganisms; bacteria, yeast, and filamentous fungi.

When this is helpful

Capabilities

Precision Fermentation

Exploit the cellular machinery to make functional natural ingredients.

Use microorganisms to produce high value proteins, enzymes, lipids, bioactives and more.

When this is helpful

Capabilities

Optimising growth conditions of microorganisms

Optimise your fermentation conditions for maximum yield and purity.

We design media and growth environments tailored to your specific microbial strain. Ensuring an efficient, cost-effective and maximised yields of your target compound.

When this is helpful

Capabilities

Technology transfer

Get ready for manufacturing with a complete, transferable process package.

When you are ready to produce your product, we can provide a complete technical package to provide to a commercial manufacturer.

When this is helpful

Capabilities

Ready to transform your business?

Get started today!

Contact us to discuss your specific business needs.