NanoLayr has gone where very few have - manufacturing commercial-scale nanofibre textiles - so their IP is vital. With the support of Callaghan Innovation, their IP strategy will grow as the business does.

At a glance

- NanoLayr is one of the very few who make high-performance nanofibre textiles on a commercial scale, used in everything from composite reinforcement, to air filtration, beauty treatments, and acoustics.

- To safeguard its intellectual property (IP) as it scales, NanoLayr has instituted an IP strategy, with support from partners including Callaghan Innovation.

- With a vision to become the world’s largest deep tech manufacturer of nanofibre textiles, the business has experienced rapid growth, including significant revenue growth.

In rolling out this programme, we knew we needed to engage with the right types of agencies and partners to support us. Beyond IP is a great initiative, and part of a wider Callaghan Innovation suite of programmes with the potential to build and shape business capability in many ways.

- Ray Connor - CEO, NanoLayr

From Earth to Venus, commercial manufacturing like no other

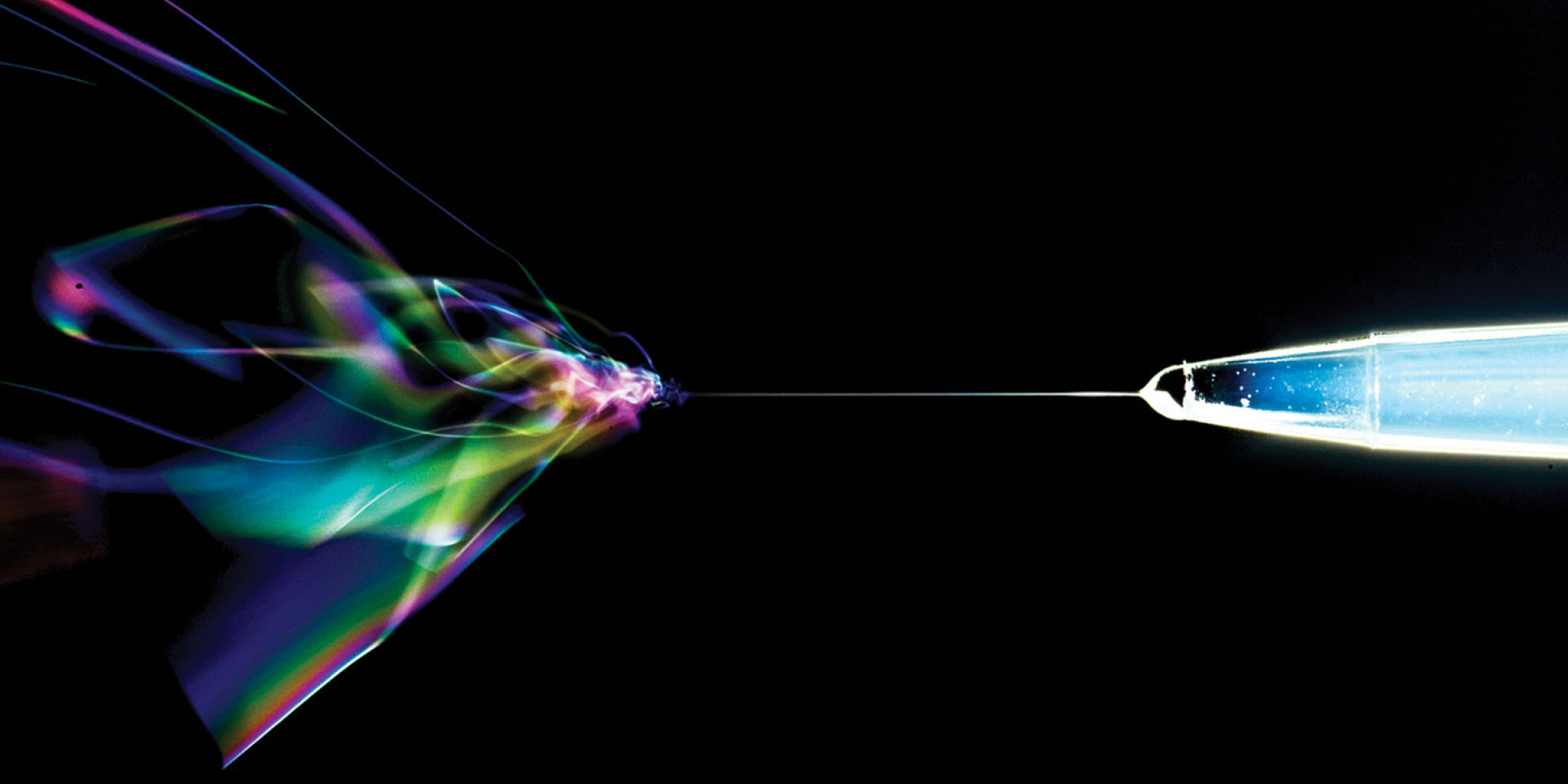

NanoLayr produces enough nanofibre from 1kg of raw material that it would stretch from Earth to Venus when placed end to end.

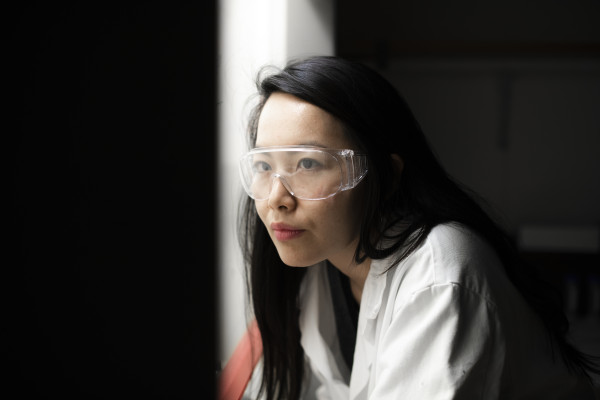

Now that’s large-scale manufacturing, especially when you compare it: “We have PhDs start work in the business who, in their many years of academic work, have managed to maybe produce an A4-size piece of nanofibre textile,” says NanoLayr CEO Ray Connor. “When they see these thousands of metres rolling off our machines, they can’t believe it.”

Auckland-based NanoLayr manufactures high-performance nanofibre textiles, with its core platform technologies used in air filtration, composites reinforcing, skincare and beauty, and acoustics.

Having founded the business in 2009, the original aim was to create the world’s best air filter. But the founders could see further benefits, the trouble being only lab-scale technology existed to create it. So they set about creating their own machine, manufacturing nanofibre textiles on a commercial scale - one of the few to do so.

An IP strategy to grow with the business

Getting to that point has taken years of R&D and research partnerships, which has included accessing a range of Callaghan Innovation support, not least R&D Experience Grants and R&D Career Grants.

For NanoLayr, creating a wider understanding of how intellectual property (IP) can create, and erode, value is playing an important role in the business’ growth story.

Having already been through Callaghan Innovation’s Beyond IP programme in its earlier stages, a change in business strategy looking at increasing global commercial opportunity for nanofibre textiles meant an overhaul of its IP approach. The business needed to ensure it was fit for purpose for its next phase of growth, and subsequently turned to its partners, including Callaghan Innovation and the Beyond IP programme, once again.

“In rolling out this programme, we knew we needed to engage with the right types of agencies and partners to support us. Beyond IP is a great initiative, and part of a wider Callaghan Innovation suite of programmes with the potential to build and shape business capability in many ways,” says Connor.

With support from its advisors, NanoLayr identified eight areas where IP drives value in the business, encompassing everything from human and relationship capital, to IP registers and product and process IP.

Connor says a key part of the work involved embedding a thorough understanding of NanoLayr’s IP and its stewardship within the culture, operationalising that also throughout the business. This has included different work streams being captured throughout the business in areas such as workplace training, documentation, access levels, annual reviews, and audits.

“The most vulnerable we’ll be to an IP breach or leak is at the weakest part of our process, which is the individual who doesn’t understand the value of IP. This work has allowed us to create an internal conversation to make sure everyone in the business is aware of their role in the creation and protection of our IP,” says Connor.

A focus on the future

NanoLayr has continued to scale. It moved from its former 275 square metre home to a 5,500 square metre purpose-built facility and has grown its number of electrospinning machines for manufacturing from one to six, with a further 10 planned.

The business has also experienced an explosion in demand for its products, leading to significant revenue growth, and a drastic increase in staff numbers. COVID-19 played a huge role, with demand increasing for its filtration media, but Connor says the biggest growth has actually come from its DermaLayr beauty and skincare technology.

With NanoLayr eyeing up an Initial Public Offering (IPO), the future is bright for the deep-tech manufacturers.

“Our move towards an IPO is a way for us to cement our capability in this technology, and to ultimately make it not just part of NanoLayr’s story, but of New Zealand’s story. That’s a big driver for us,” says Connor.