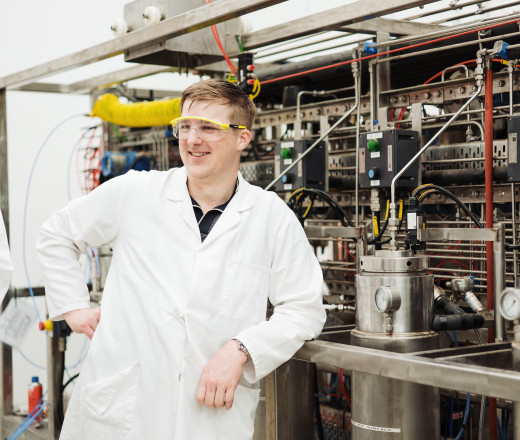

Create food process technologies to enable production of high value ingredients from plants, marine, meat, apiary or microbial sources.

We help you develop and scale these processing technologies from bench to semi-commercial production scale through our partnership with NZFIN and in particular, The FoodBowl.

Our food processing technologies allow you to recover or make functional ingredients like oils, proteins, peptides and carbohydrates from complex biological materials including byproduct streams.

Whether you're creating a premium health product or recovering value from by-product streams, we tailor our processing technologies to maximise yield, potency, and safety - and get you ready for scale-up and commercialisation.

When this is helpful

Capabilities

Supercritical fluid and liquified gas extraction

Isolate compounds in your natural resource using a sustainable and solvent residue free process.

Supercritical fluid extraction is a method that separates one component from another by using supercritical fluid as the solvent. Our world-class team are experts in optimising extraction conditions and technology transfer, so you can maximise the value of your natural product and scale faster.

Learn more

Membrane fractionation

Isolate compounds in aqueous streams and organic solvent solutions (under development) using membrane fractionation.

Membrane fractionation is a method that separates molecules based on their size when dissolved in a liquid solvent. Our world-class team are experts in optimising processing conditions and technology transfer, so you can maximise the value of your natural product and scale faster. We have different scales of equipment that allows separation of solutions from 100’s of mls to 1000’s of litres.

Learn moreDrying, partial evaporation and mechanical dewatering technologies

We offer scalable expertise in a variety of drying, partial evaporation and mechanical dewatering technologies in partnership with The FoodBowl.

Technologies for drying solids include:

- Freeze-drying

- Vacuum tray drying

- Heat-pump tray drying

- Technologies for partial evaporation of liquids include:

- Batchwise rotary vacuum evaporation suitable for both aqueous and solvent-based solutions

- Continuous centritherm - for producing juice concentrates and concentrated protein or peptide solutions.

Mechanical dewatering technologies include:

- Continuous flow screw and belt presses

- Batchwise hydropress

Ready to transform your business?

Get started today!

Contact us to discuss your specific business needs.